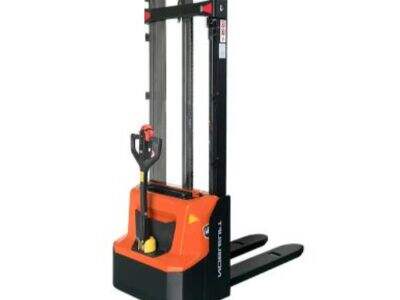

Electric forklifts keep cold storage running smoothly. In these highly-specialized applications where temperature regulation is paramount, the right equipment can mean a significant difference in both efficiency and safety. Here, we share both the 7 benefits of electric forklifts in cold storage and continue to discuss what you need to consider when looking at electric forklifts in these challenging settings.

Benefits of Electric Forklifts in Cold Storage

There are many benefits of using electric forklift in cold storage applications. The main advantages include: they are intended to operate efficiently at low temperature without fuel combustion. It is due to this, they perfectly suitable for indoor use (also in cold stores with exhaust emissions being hazardous). What’s more, electric trucks are far quieter than their internal combustion counterparts, providing a less noisy in-house atmosphere for operator employees. They are also very simple to handle and are ideal for small spaces such as moving down the narrow corridors of cold storage. What’s more, is that electric forklifts are easier to maintain than gas-powered counterparts which in turn can lead to less downtime and lower maintenance costs. In general, using electric forklifts in cold storage can result in productivity gains as well as long-term safety and cost benefits.

Selecting the Best Electric Forklift for Cold Storage

If you are choosing an electric forklift for cold storage, then here are things you should consider to obtain maximum performance and efficiency. Insulation – Firstly make sure the forklift has enough insulation against low temperatures which are usually present in cold storage buildings. The installation of insulation contributes to saving the forklift from potential freeze-ups and damage. Second, the battery system of the selected forklift must be strong enough to run continually in cold environments. If you’re looking for a battery with cold weather performance ability, good batteries do eliminate the drawback of power reduction in sub-freezing temperatures. And, if you are using a forklift in a cold storage environment, also take into account the right tires. This can help with traction and safety on slippery or wet surfaces. Finally, suiting the specific load capacity and lifting height requirements of the cold storage operations would be vital to selecting an electric forklift that can meet all necessary work requirement. Considering these factors will help businesses choose the right electric forklift for cold storage applications while ensuring performance and productivity are optimized.

Electric Forklift are an important part of daily operations at cold storage locations because the proper temperature is key to keeping perishable products in good shape. If you’re using electric forklifts in cold storage, there are a few things that operators should be aware of to make sure their equipment can run as efficiently and effectively as possible.

Standard Temperature Cut-to-fit Electric Forklift Application Issues in Cold Storage

Diminished battery efficiency is a common problem electric forklifts encounter in cold storage. Cold weather can decrease the power of a battery more rapidly, resulting in shorter runtime and less productivity. To avoid this problem, operators can use battery heaters or insulated covers made to keep your battery at the proper temperature.

Lower tire traction in cold storage environments may also be a problem for operators. Tire Hardness - Cold temperatures can cause the rubber to contract and harden so tires may become too firm. To prevent this, operators should periodically check the pressure of tires and use special ones for cold storage applications.

What to Consider when Choosing a Wholesale Electric Forklift Vendor

In choosing the wholesale electric forklift distributor cold storage operations, there are several important things to consider: Choosing a supplier with a line of electric forklifts made to survive in cold storage that include built-in insulated cabins and cold-resistant parts is key.

Operators should also search for a supplier who offers ongoing maintenance and support services to keep their electric forklifts running smoothly. The pricing has to be competitive and the finance terms flexible for a modern cold storage facility.

Maintenance and Care Tips for Electric Forklifts Used in Cold Storage

To get optimized productivity and longevity of electric mobile lift in cold storage environment, it should be properly maintained. How to Prevent Ice and Snow in Forklift During the winter, forklift operators should clean off their equipment on a regular basis so that snow/ice does not accumulate and impact performance.

You should also adhere to the manufacturer’s prescribed service interval and inspect and maintain battery, tires and other major systems. Operators also need to ensure their team are properly trained in forklift use and safety measures, to avoid accidents and maintain effective operation within cold storage units.

Electric Forklifts and the Cold Warehouse Electric fork trucks are integral to cold storage work, but there are some special things operators need to take into account in order to get good performance from them. By tackling common usage challenges, selecting the appropriate wholesale supplier and caring for your fleet properly, operators can guarantee their electric lift trucks are operating at peak efficiency… even with cold storage.

Table of Contents

- Benefits of Electric Forklifts in Cold Storage

- Selecting the Best Electric Forklift for Cold Storage

- Standard Temperature Cut-to-fit Electric Forklift Application Issues in Cold Storage

- What to Consider when Choosing a Wholesale Electric Forklift Vendor

- Maintenance and Care Tips for Electric Forklifts Used in Cold Storage

EN

EN

AR

AR

FR

FR

DE

DE

IT

IT

KO

KO

ES

ES

CS

CS

DA

DA

PT

PT

SK

SK

SR

SR

ID

ID

TL

TL

UK

UK

TR

TR

TH

TH

HU

HU

ET

ET

SQ

SQ

VI

VI

LT

LT

RU

RU

FI

FI

EL

EL

HI

HI

HR

HR

NL

NL

MT

MT

FA

FA

IS

IS

MK

MK

GA

GA

BN

BN

LA

LA

MY

MY

SV

SV

RO

RO

NO

NO

MS

MS